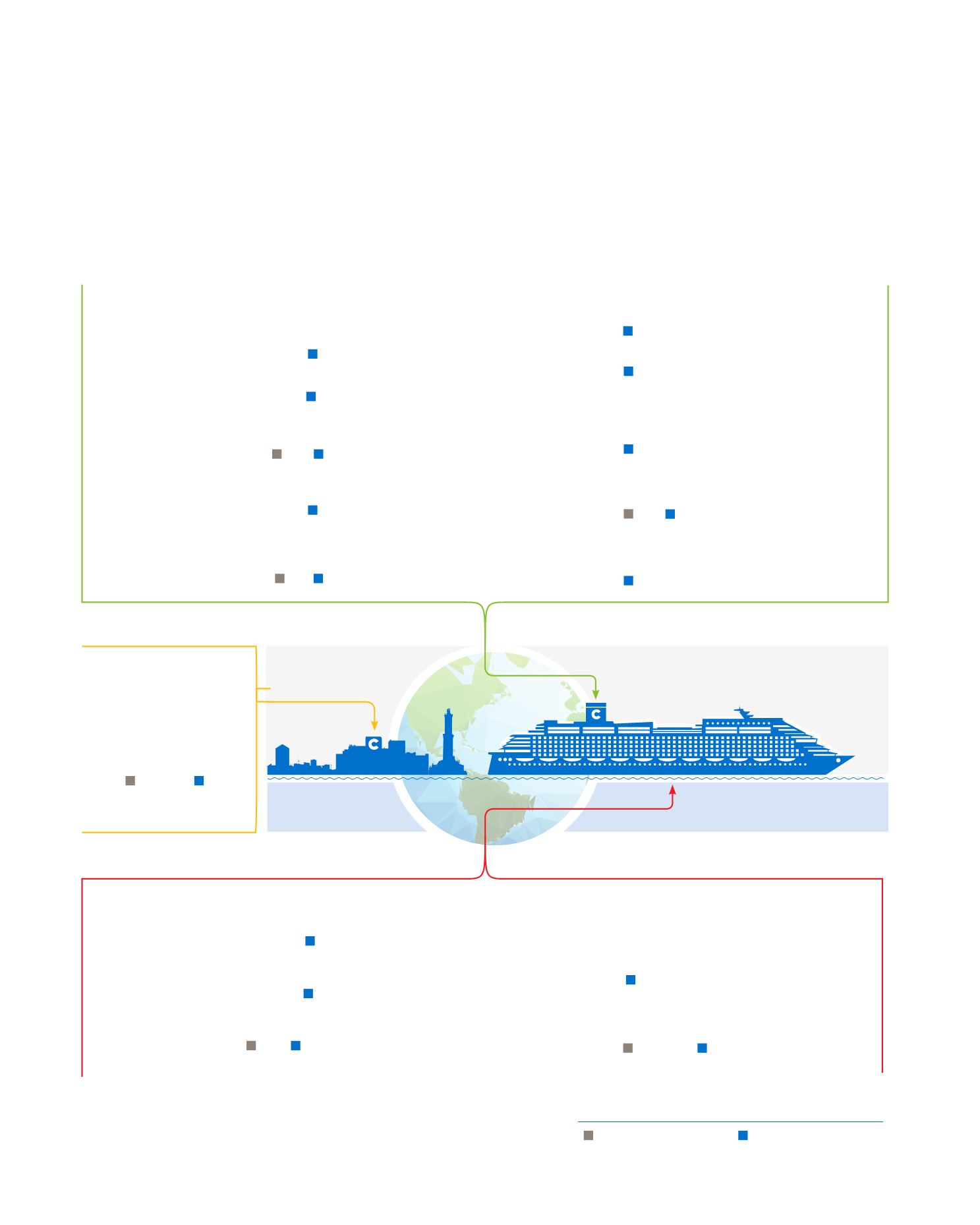

SHIP

OPERATION AND

MAINTENANCE

INITIATIVES

Redesigning more fuel-efficient itineraries.

100%

Optimum ship trim

evaluation systems.

+13% 33%

Optimum use of shipboard diesel

generators at sea and in port.

100%

Planned maintenance of the hull and regular

scheduled cleaning of the propellers.

100%

Installation of technology to increase

the amount of waste heat recovered

from engine cooling water.

+4% 97%

Optimum use of the HVAC (heating,

ventilating and air conditioning)

system in the public areas

(Demand Flow Phase One where

applicable).

100%

Optimum regulation

of the HVAC system.

+15% 70/75%

Replacement of existing

light globes with low

power consumption

LED lamps in the Genoa

Headquarters.

Completed 100%

Gradual replacement of existing

light globes with low power

consumption LED lamps.

Completed 100%

Installation of frequency converters for electric engines

for ventilators, for engine room air conditioning

stations and for engine room auxiliary service pumps.

100%

Use of state-of-the-art

ecological coatings.

100%

Rational management of incinerators.

100%

Gradual installation of an automatic lighting

control system designed to adjust the external

lighting of the ship in accordance with the

current sunlight intensity.

100%

Training and education for all cabin

service personnel with regard to correct

energy use.

100%

Introduction of key-card holders, so that

lighting etc. can only be switched on when the

cabin is occupied.

+13% 33%

Use of voyage optimization tools.

100%

REDUCTION

OF FUEL USE

AND ENGINE EMISSIONS

IMPLEMENTATION 2015 TOTAL IMPLEMENTATION

Energy efficiency: the projects