Page 55 - BILANCIO DI SOSTENIBILITÀ 2019 RISULTATI E PROSPETTIVE

P. 55

55

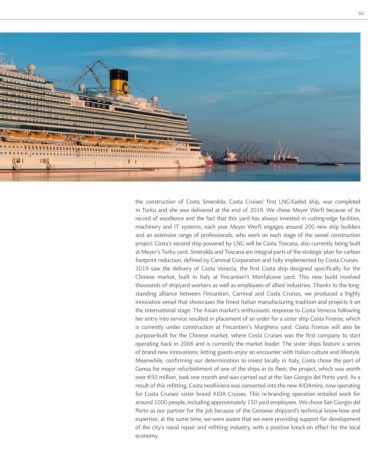

Design and The design and construction of passenger ships requires in-depth knowledge of naval the construction of Costa Smeralda, Costa Cruises’ first LNG-fueled ship, was completed

construction: technology and careful consideration of safety and reliability issues as well as the – increasingly in Turku and she was delivered at the end of 2019. We chose Meyer Werft because of its

important – environmental sustainability aspects. For this reason, together with Carnival for

record of excellence and the fact that this yard has always invested in cutting-edge facilities,

shipbuilding many years Costa has entrusted its new building projects to the best shipyards, concentrating machinery and IT systems; each year Meyer Werft engages around 200 new ship builders

its investments in European yards with an international standing. European shipyards stand and an extensive range of professionals, who work on each stage of the vessel construction

out on account of their quality, expertise and technological know-how; it is precisely because project. Costa’s second ship powered by LNG will be Costa Toscana, also currently being built

of this process of capacity building and reciprocal influence that Costa and Carnival are at at Meyer’s Turku yard. Smeralda and Toscana are integral parts of the strategic plan for carbon

the forefront of contemporary shipbuilding, thus contributing to advancement of the cruise footprint reduction, defined by Carnival Corporation and fully implemented by Costa Cruises.

industry and global shipping in general. Europe’s shipyards build the world’s most innovative 2019 saw the delivery of Costa Venezia, the first Costa ship designed specifically for the

vessels, making the construction, maintenance and conversion of ships a real growth industry. Chinese market, built in Italy at Fincantieri’s Monfalcone yard. This new build involved

Over time, Costa has forged solid links with Fincantieri in Italy and Meyer Werft in Germany thousands of shipyard workers as well as employees of allied industries. Thanks to the long-

and Finland, generating a very positive economic impact. According to a study commissioned standing alliance between Fincantieri, Carnival and Costa Cruises, we produced a highly

by the Costa Group and published by Deloitte in 2019, our total shipbuilding impact across innovative vessel that showcases the finest Italian manufacturing tradition and projects it on

Europe amounts to €4.5 billion and 20,300 full-time jobs. Naturally, the largest shipbuilding the international stage. The Asian market’s enthusiastic response to Costa Venezia following

impact is concentrated in the shipyard locations – Italy, Germany and Finland – however the her entry into service resulted in placement of an order for a sister ship Costa Firenze, which

benefit also extends to other countries, including Romania, Norway, Sweden, the UK, Poland is currently under construction at Fincantieri’s Marghera yard. Costa Firenze will also be

and the Netherlands. Shipbuilding accounts for a significant portion (36%) of our overall purpose-built for the Chinese market, where Costa Cruises was the first company to start

generated value, due to the investment plan that the Costa Group has launched with the operating back in 2006 and is currently the market leader. The sister ships feature a series

construction of new ships at the Fincantieri shipyards in Marghera and Monfalcone (Italy) as of brand new innovations, letting guests enjoy an encounter with Italian culture and lifestyle.

well as at the Meyer Werft shipyards in Papenburg (Germany), and in Turku (Finland), with Meanwhile, confirming our determination to invest locally in Italy, Costa chose the port of

all that this means in terms of indirect and induced impacts. Costa also invests in dry-docking Genoa for major refurbishment of one of the ships in its fleet; the project, which was worth

and in upgrades on its existing ships, introducing state-of-the-art technology and amenities over €50 million, took one month and was carried out at the San Giorgio del Porto yard. As a

influencing global shipping as a whole. For example, at Group level, Costa owns a 33% stake result of this refitting, Costa neoRiviera was converted into the new AIDAmira, now operating

in Chantier Naval De Marseille, the Mediterranean’s premier ship repair and refitting yard, for Costa Cruises’ sister brand AIDA Cruises. This re-branding operation entailed work for

and a 61% stake in Ecospray Technologies, leader in the production of scrubbers (Advanced around 1000 people, including approximately 150 yard employees. We chose San Giorgio del

Air Quality Systems - AAQS), installed fleetwide. Porto as our partner for the job because of the Genoese shipyard’s technical know-how and

The yards are accompanying the Company on the path to change in the direction of a progressive expertise; at the same time, we were aware that we were providing support for development

and substantial reduction of environmental impact of operations without compromising of the city’s naval repair and refitting industry, with a positive knock-on effect for the local

on safety, in line with Costa’s top priorities. By virtue of our partnership with Meyer Werft, economy.